ERW steel pipe is the straight seam resistance welding pipe, the English Electric Resistance Welding, abbreviation for ERW.

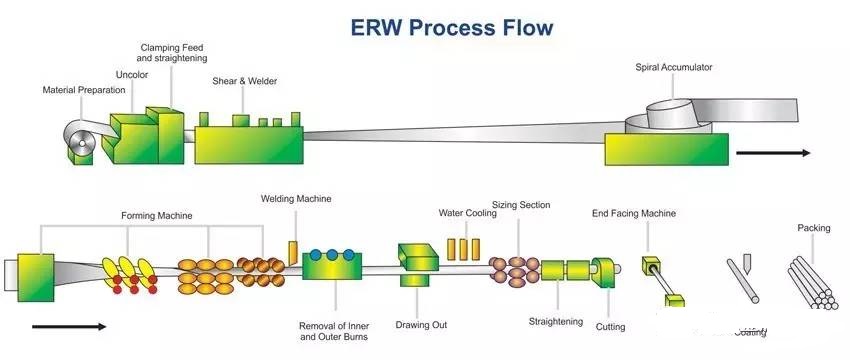

ERW steel pipe is produced by forming the hot rolled rolling plate through the molding machine, melting the edge of the pipe blank and performing pressure welding under the extrusion roller. The uniform wall thickness can be controlled at about ± 0.2mm.ERW production process has high production efficiency, low cost, material saving, easy automation and other characteristics, widely used in aviation, aerospace, energy, electronics, automobile, light industry and other industrial fields.

| General Standard and Application of ERW Steel Pipe | ||

| S.N. | Standards | Application |

| 1 | ASTM A53 | Seamless and Welded Black and Hot-dipped Galvanized Steel Pipe |

| 2 | ASTM A135 | Electric-resistance-welded(ERW) steel pipe in NPS 2 to NPS 30 |

| 3 | ASTM A178 | Electric-Resistance-Welded(ERW) Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes |

| 4 | ASTM A214 | Electric-Resistance-Welded(ERW) Carbon Steel Heat-Exchangerand Condenser Tubes |

| 5 | ASTM A250 | Electric-Resistance-Welded(ERW) Ferritic Alloy-Steel Boiler and Superheater Tubes |

| 6 | ASTM A333 | Welded Steel Pipe for Low Temperature Service |

| 7 | ASTM A334 | Welded Carbon and Alloy Steel Tubes for Low Temperature Service |

| 8 | ASTM A500 | Cold-Formed Welded Carbon Steel Structural Tubing in Rounds and Shapes |

| 9 | ASTM A501 | Hot-Formed Welded Carbon Steel Structural Tubing |

| 10 | ASTM A513 | Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing |

| 11 | ASTM A523 | Plain end Electric Resistance Welded Steel Pipe for High Pressure Pipe Type Cable Circuits |

| 12 | ASTM A618 | Hot-Formed Welded High-Strength Low-Alloy Structural Tubing |

| 13 | ASTM A795 | Black and Hot-Dipped Zinc-Coated (Galvanized) Welded Steel Pipe for Fire Protection Use |

| 14 | EN 10208-1 | Steel Pipes for Pipelines for Combustible Fluids-Pipes of Requirement Class A |

| 15 | EN 10208-2 | Steel Pipes for Pipelines for Combustible Fluids-Pipes of Requirement Class B |

| 16 | EN 10217-1 | Welded Steel Tubes for Pressure Purposes-Non-alloy steel tubes with specified room temperature properties |

| 17 | EN 10217-2 | Welded Steel Tubes for Pressure Purposes-Electric Welded Non-alloy and Alloy Steel Tubes with Specified Elevated Temperature Properties |

| 18 | EN 10217-3 | Welded Steel Tubes for Pressure Purposes-Alloy fine grain steel tubes |

| 19 | EN 10217-4 | Welded Steel Tubes for Pressure Purposes-Electric Welded Non-alloy and Alloy Steel Tubes with Specified Low Temperature Properties |

| 20 | EN 10217-5 | Welded Steel Tubes for Pressure Purposes-Submerged Arc Welded Non-alloy and Alloy Steel Tubes with Specified Elevated Temperature Properties |

| 21 | EN 10217-6 | Welded Steel Tubes for Pressure Purposes-Submerged Arc Welded Non-alloy Steel Tubes with Specified Low Temperature Properties |

| 22 | EN 10224 | Non-alloy Steel Tubes for the Conveyance of Water and Other Aqueous Liquids |

| 23 | EN 10255 | Non-alloy Steel Tubes Suitable for Welding and Threading |

| 24 | EN 10288 | Steel Tubes and Fittings for Onshore and Offshore Pipelines |

| 25 | EN 10296-1 | Welded Circular Steel tubes for Mechanical and General Engineering Purposes-Non-alloy and Alloy Steel Tube |

| 26 | EN 10305-2 | Steel Tubes for Precision Applications-Welded Cold Drawn Tubes |

| 27 | EN 10305-3 | Steel Tubes for Precision Applications-Welded Cold Sized Tubes |

| 28 | EN 10305-6 | Steel Tubes for Precision Applications-Welded Cold Drawn Tubes for Hydraulic and Pneumatic Power Systems |

| 29 | DIN 30670 | Polyethylene Coatings on Steel Pipes and Fittings |

| 30 | ISO 3183 | Steel Pipe for Pipelines Transportation Systems |

| 31 | API 5L | Specification for Line Pipe |